YOUR PARTNER FOR HYGIENIC FILLING AND PACKAGING TECHNOLOGY

Welcome to Ampack, the technology leader for hygienic filling and packaging machines based in Königsbrunn, Germany. As part of the Ceratech Group, we offer innovative filling and sealing machines for liquid and viscous foods, as well as aseptic thermoforming machines.

Ampack accompanies you throughout the entire life cycle of your machine. We support you from the initial consultation to determine your specific requirements, all the way through to the planning and production of customized solutions for your company. Our comprehensive service offering ensures smooth and long-term operation.

Our Solutions

- Dairy and plant-based products: e.g. yogurt, cottage cheese, coffee cream, pudding and desserts

- Drinks to-go: e.g. Café latte, milk-based drinks, protein shakes

- Baby food and clinical nutrition

- Delicatessen and dips: e.g. hummus, vegan spreads and salsa

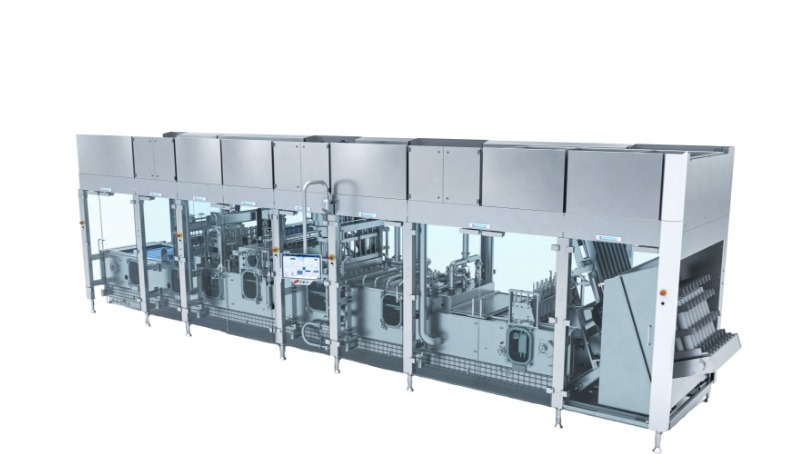

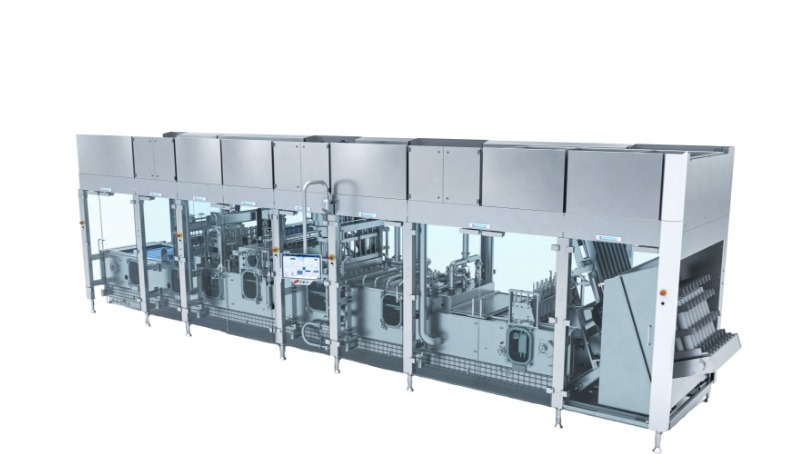

FCL

- High product safety with enclosed machine tunnel

- Aseptic execution with double chamber design and packaging sterilization with H₂O₂

- Fully automatic CIP and SIP

LFS

- Open frame design, easy operation and maintenance

- Chemical-free packaging disinfection

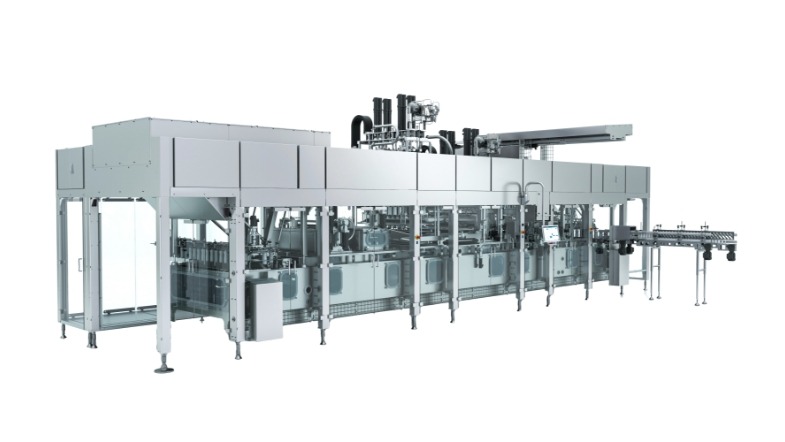

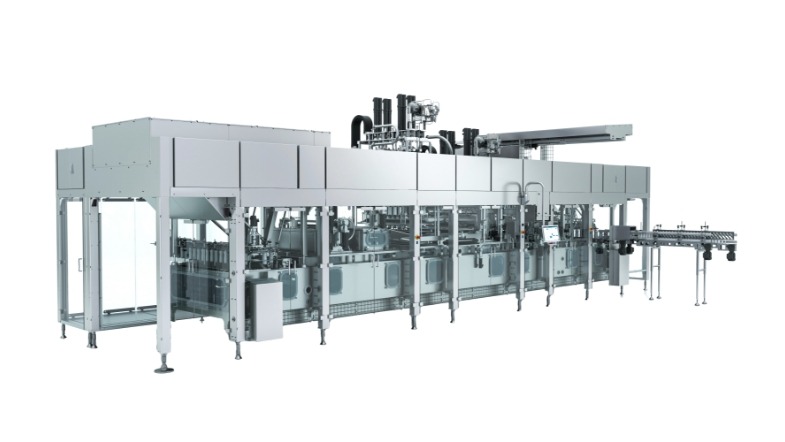

TFA

- Meeting highest food safety standards (FDA)

- Fully enclosed aseptic tunnel with continuous monitoring of sterile air overpressure

- Fully automatic CIP and SIP

FBL

- Filling different bottle volumes from 50 – 1,500 ml

- Flexibility in bottle formats and materials (HDPE, PP, PET)

- Decontamination of bottles with vaporized hydrogen peroxide

INNOVATIVE SERVICES ACCORDING TO YOUR NEEDS

Spare parts

Our experts will advise you on the planning and storage of spare and wear parts, so you can respond quickly and flexibly.

Technical support

Whether quick help from a distance or directly on site from our experienced service technicians – if things have to happen quickly, we are there for you.

Maintenance

We carry out machine inspections, maintenance and overhauls upon request. With our service contracts, you secure fixed maintenance intervals and schedules.

Modernization

With individually tailored modernization packages, we ensure that your machine remains up to date with the latest technology.

Training

We train your staff when commissioning the machines and whenever you need it.

Lab services

CONTACT US

Do you have any questions about our filling machines or services? Our team of experts will be happy to help you at any time.

Use our contact form or call us directly – we look forward to your inquiry!